Welcome

We Are Best In Industry

Fusce pulvinar, velit a posuere maximus, velit metus lacinia arcu, ultrices volutpat sapien neque vitae diam.

Welcome

We Are Best In Industry

Fusce pulvinar, velit a posuere maximus, velit metus lacinia arcu, ultrices volutpat sapien neque vitae diam.

of Universe Steel Ltd.

MESSAGE FROM MANAGING DIRECTOR

.Ladies and gentlemen, Assalamualaikum,

Greetings and welcome to the world of GRACE CONSTRUCTION & UNIVERSE STEEL LTD. The encouragement provided to build a highly skilled and creative team, Which is reinforced by the state-of-the-art infrastructure, Integrity and excellence? We are committed to having a good partnership, transparency, reliability with our Clients rather than Client-Contractor relationship. Our clients are fully aware that We have the skills, resources and expertise and most importantly the ability to Complete their projects to the highest standards on time. Our mission is to deliver high-quality, cost-effective projects on schedule by employing And supporting motivated, flexible and focused teams. We value the importance Of our relationships and will continue to remain fair and true in our dealings with all Employees, vendors and partners. We are very proud out our achievements and accomplishment till date and we are Planning for ambitious targets to achieve in the near future. With Kind & Regards

Engr. Md. Shamsuzzaman Shamim

Managing Director

Cell: 01719123758

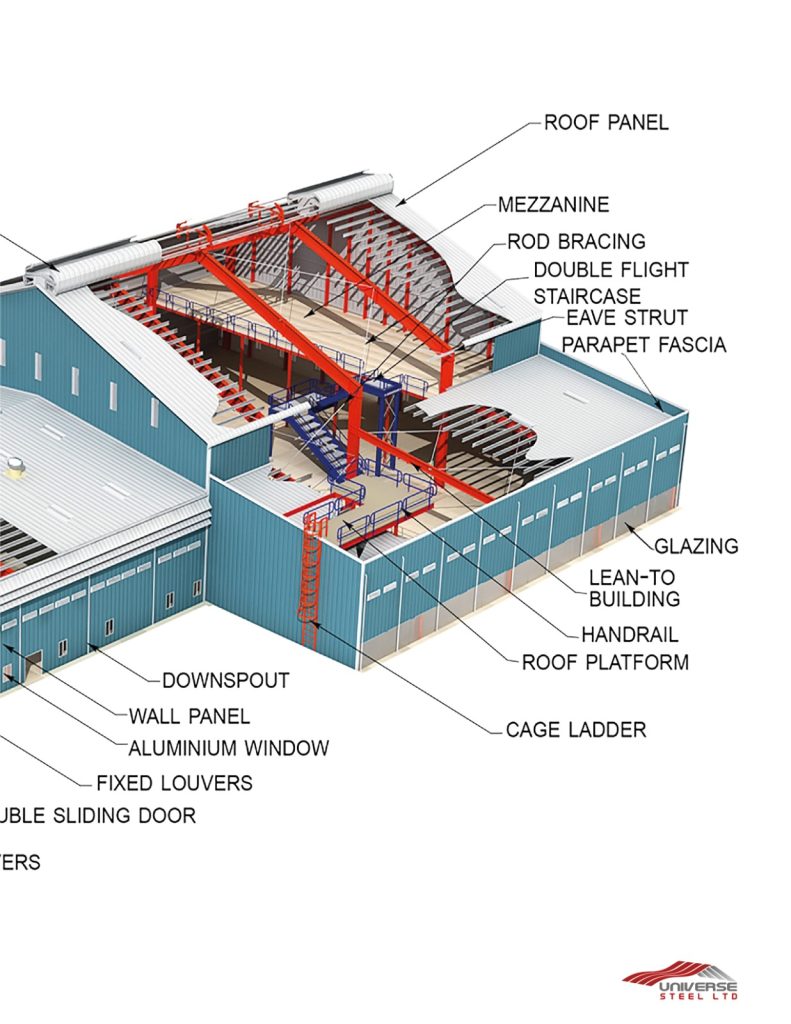

OUR PRODUCTS:

- • Pre-Engineered Building

- • Standard Framing System

- • Structural Sub System

- • Crane System

- • Overhead Canopy

- • Car Parking System

- • Double/Single Sliding Doors/ Roll Up Doors

- • Fixed Louvers

- • Translucent Panels

- • Ridge Ventilators

- • Insulation

- • Anchor Bolts

- • Canopies

- • Fascia’s

- • Roof Monitors

- • Other Structural Products

- • Portal Frame

- • Star Column

- • Iced Column

- • And Many Other

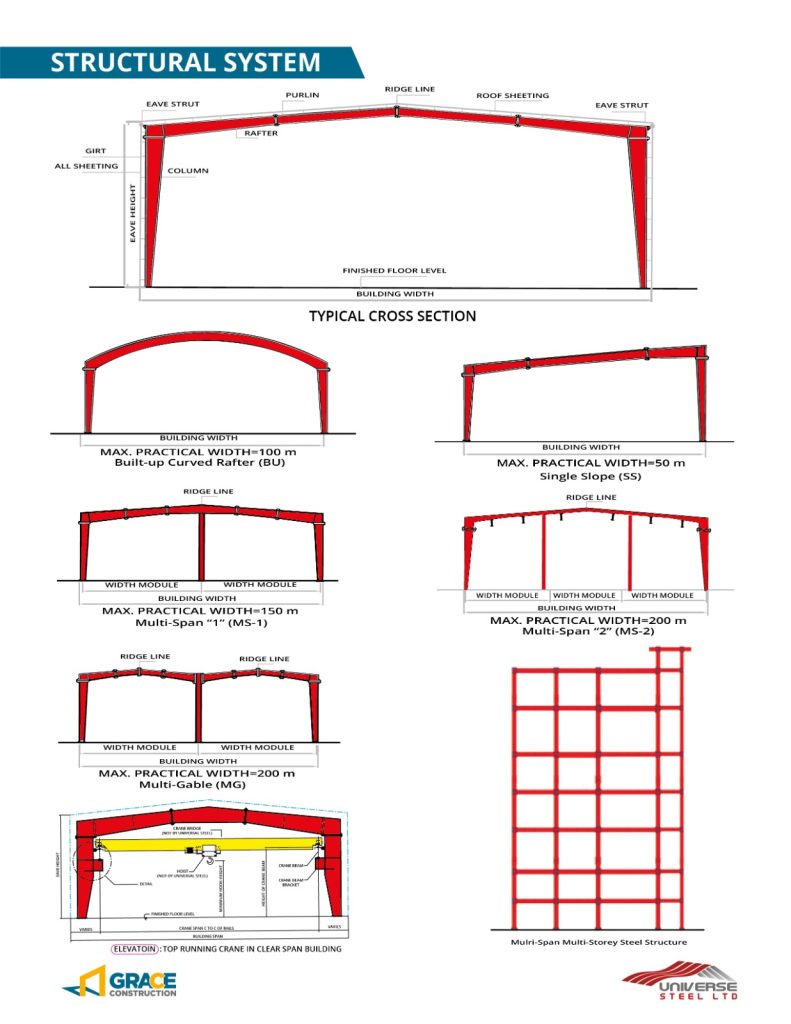

FEATURES OF UNIVERSE STEEL LIMITED:

- Proper Structural designing as per applicable codes with design challenges

- Higher & latest methods of stability analysis as per applicable codes

- Economical solution with client’s demand

- Space flexibility with larger span

- Adjustable design & flexibility for birth vertical & lateral expansion

- Environment Friendly

- Faster construction considering proper erection rules

- Minimum maintenance

- One Stop Solution

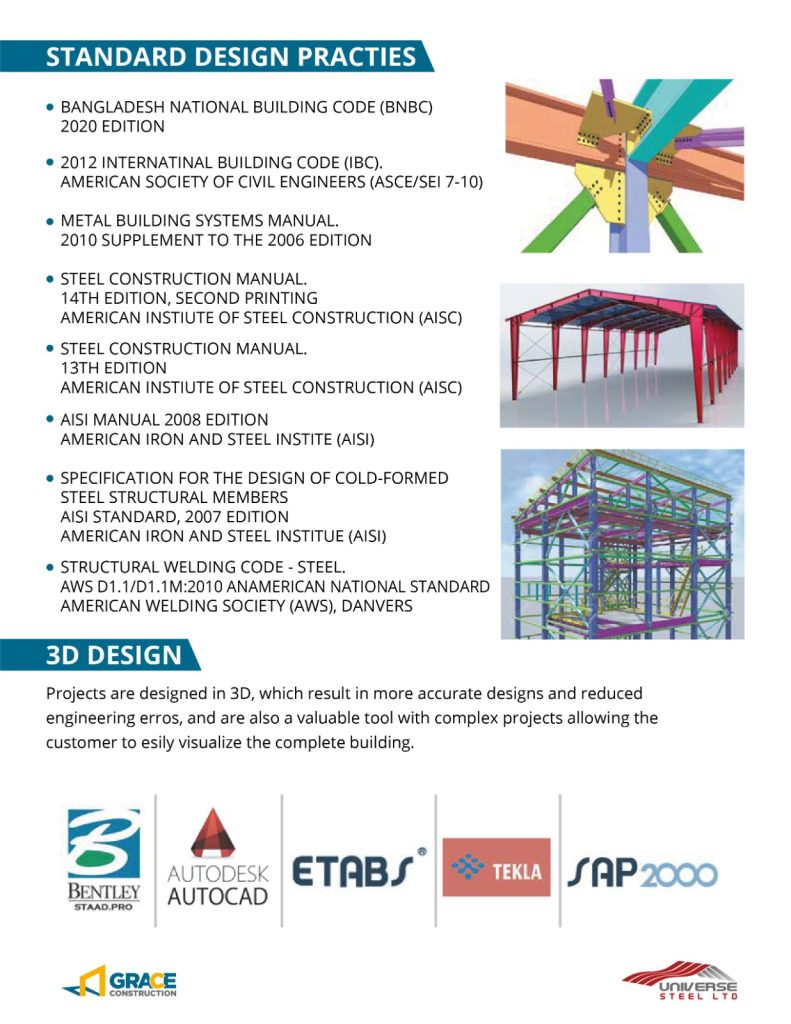

STANDARD DESIGN PRACTIES:

- BANGLADESH NATIONAL BUILDING CODE (BNBC)2020 EDITION

- 2012 INTERNATINAL BUILDING CODE (IBC). AMERICAN SOCIETY OF CIVIL ENGINEERS

(ASCE/SEI 7-10)

- METAL BUILDING SYSTEMS MANUAL.2010 SUPPLEMENT TO THE 2006 EDITION

- STEEL CONSTRUCTION MANUAL.14TH EDITION, SECOND PRINTINGAMERICAN INSTIUTE OF STEEL CONSTRUCTION (AISC)

- STEEL CONSTRUCTION MANUAL.13TH EDITIONAMERICAN INSTIUTE OF STEEL CONSTRUCTION (AISC)

- AISI MANUAL 2008 EDITIONAMERICAN IRON AND STEEL INSTITE (AISI)

- SPECIFICATION FOR THE DESIGN OF COLD-FORMEDSTEEL STRUCTURAL MEMBERS

AISI STANDARD, 2007 EDITIONAMERICAN IRON AND STEEL INSTITUE (AISI)

- STRUCTURAL WELDING CODE -STEEL.AWS D1.1/D1.1 M:2010 ANAMERICAN NATIONAL STANDARDAMERICAN WELDING SOCIETY (AWS), DANVERS

USL ERECTION PROCESS:

- Understanding Engineering Documents

- Erection

- Setting Out Of Anchor Bolts

- Daily Safety Meeting

- Assembling Members

- Erection

USL IMPORTED PRODUCTS

- MS Plates

- Cold Formed Sheet

- Cold Rolled Sheed/Color Coated Profile Sheet

- Structural Nut-Bolts, Screws

- MIG Ware, Electrode

Why Choose Us

All Maintenance

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

Genarel Contract

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

Automobiles

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

Mechanical Parts

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

Petroleum

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

24×7 Support

Stop loss and take profit orders will help secure your investment. The system will automatically execute trades

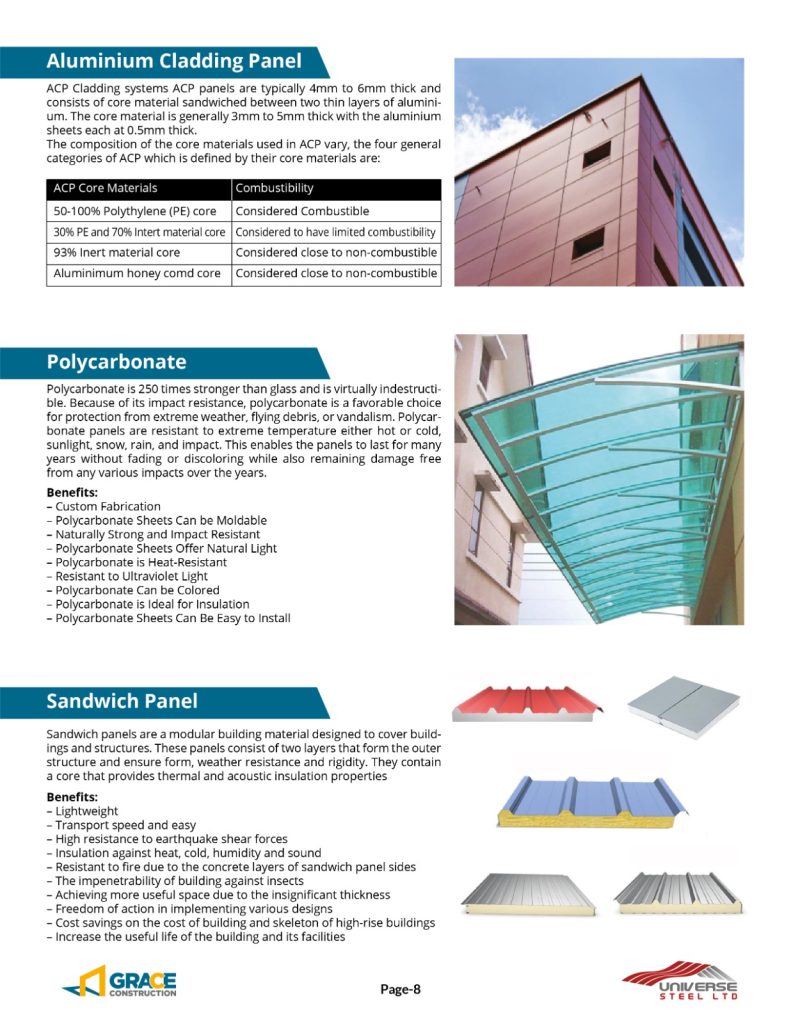

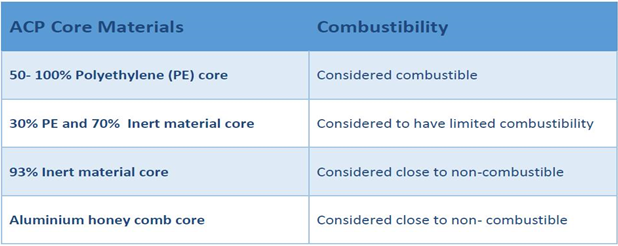

ALUMINIUM CLADING PANEL:

ACP Cladding systems ACP panels are typically 4mm to 6mm thick and consists of core material sandwiched between two thin layers of aluminum. The core material is generally 3mm to 5mm thick with the aluminum sheets each at 0.5mm thick.

The composition of the core materials used in ACP vary, the four general categories of ACP which is defined by their core materials are:

EPOXY FLOORING SOLUTION:

Epoxy systems are a combination of resins and hardeners. When resin and hardener mix together then create a hard-plastic coating bonded to your floor. Epoxy flooring materials are so strong that it is used in heavy traffic areas such as industrial harsh environments, hospitals and sports facilities. Grace Construction offering you the best Epoxy floor price in Bangladesh.

Benefits:

- High scratch and impact resistance.

- Durable and Tough Impervious

- High gloss, appealing finish

- Variable thicknesses for versatile application Attractive, bright color options

- High-Temperature & High Abrasion Resistant

- Impact and Pressure Resistant

- Slip Resistant Easy to Clean

FLOOR HARDENER SOLUTION:

surface hardener is a formulated chemical compound (silicate liquid) that is used after pouring concrete to increase the concrete’s hardness, reduce the concrete’s permeability and to dustproof the concrete as it solidifies. Surface hardeners provide a cost-effective solution to improve the service life of the concrete surface and protect it from abrasion, dusting, putting and chipping

Benefits:

- It protects against damage caused by impact punching. scraping and abrasion.

- It reduces the lifetime cost of flooring repair and maintenance.

- It improves the floor’s appearance.

- It is a cost-effective way to add color. Different colors may be used to designate different areas of the floor.

FLOOR HARDENER SOLUTION:

Polished concrete is a multi-step process where a concrete floor is mechanically ground, honed and polished with bonded abrasives in order to cut a concrete floor’s surface. It is then refined with each cut in order to achieve a specified level of appearance. Polished Concrete in Bangladesh made in and sealing to porous concrete, which uses a penetrating sealer to create a reflective surface. Polished concrete typically used in commercial plus residential projects, as it’s long-lasting and also durable under heavy foot traffic. We are providing Polish Concrete materials, tools and application service with best price in Bangladesh since 2010.

Benefits:

- Environmentally Friendly

- Seamless Surface and Excellent Aesthetics.

- Abrasion Resistant.

- Chemical Resistant

- Easily cleaned and cost effective also.

POLYCARBONATE:

Polycarbonate is 250 times stronger than glass and is virtually indestructible. Because of its impact resistance, polycarbonate is a favorable choice for protection from extreme weather, flying debris, or vandalism. Polycarbonate panels are resistant to extreme temperature either hot or cold, sunlight, snow, rain, and impact. This enables the panels to last for many years without fading or discoloring while also remaining damage free from any various impacts over the years.

Benefits:

- Custom Fabrication

- Polycarbonate Sheets Can be Moldable

- Naturally Strong and Impact Resistant

- Polycarbonate Sheets Offer Natural Light

- Polycarbonate is Heat-Resistant

- Resistant to Ultraviolet Light

- Polycarbonate Can be Colored

- Polycarbonate is ideal for Insulation

- Polycarbonate Sheets Can Be Easy to Install

PU (POLYURETHANE) FLOORING SOLUTION:

Now a days PU flooring service is growing to the international level which is much value for the real life. Polyurethane flooring, also known as PU flooring, is used in both commercial and domestic environments. PU Floors are most commonly used in industrial or factory flooring. Grace Construction providing these services for PU Flooring in Bangladesh as the best applicator as well as a contractor at affordable prices.

Benefits:

- Resistant to heavy loads

- Antistatic Anti-Corrosive

- Durable, Tough Impervious

- Hygienic Food Grade High-Temperature & High Abrasion Resistant

- Impact and Pressure Resistant

- Long Lasting Economical

- Slip Resistant Easy to Clean

SANDWICH PANEL:

Sandwich panels are a modular building material designed to cover buildings and structures.

These panels consist of two layers that form the outerstructure and ensure form, weather resistance and rigidity. They containa core that provides thermal and acoustic insulation properties

Benefits:

- Lightweight

- Transport speed and easy

- High resistance to earthquake shear forces

- Insulation against heat, cold, humidity and sound

- Resistant to fire due to the concrete layers of sandwich panel sides

- The impenetrability of building against insects

- Achieving more useful space due to the insignificant thickness

- Freedom of action in implementing various designs

- Cost savings on the cost of building and skeleton of high-rise buildings

- Increase the useful life of the building and its facilities